The workplace has always been a hub of transformation, evolving alongside technological advances. In recent years, a new wave of innovation has emerged—collaborative robots, or cobots. Unlike traditional industrial robots designed to operate independently or within isolated environments, cobots are built to work directly alongside humans. This revolution is reshaping industries and reimagining how humans and machines interact, paving the way for a more efficient and dynamic future of work.

What Are Cobots?

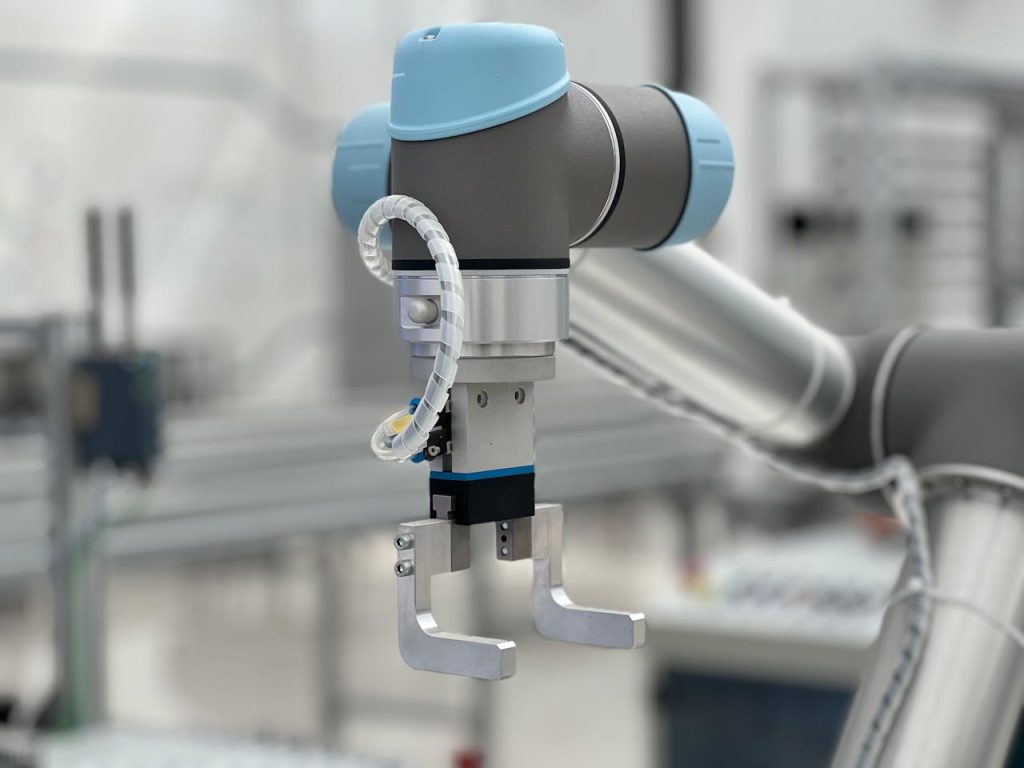

Cobots are a specialized class of robots that prioritize safety, collaboration, and adaptability. Unlike their traditional industrial counterparts, which often operate behind safety barriers, cobots are engineered to work near humans. This is possible due to advanced sensors, lightweight designs, and programming that ensures responsiveness and adaptability.

The rise of cobots represents a significant milestone in the field of robotics. These machines are designed to perform repetitive or physically strenuous tasks while humans focus on strategic and creative work. For example, while a human worker oversees production quality, a cobot can handle the heavy lifting or precision assembly that would otherwise demand significant effort. Cobots are not meant to replace human labour but to complement it, creating a synergy that enhances productivity and workplace efficiency.

The Rise of Cobots in the Workplace

Cobots represent the next phase of automation, where collaboration takes centre stage. Over the last decade, their adoption has surged as industries seek solutions that address efficiency, cost-effectiveness, and worker safety. From manufacturing and healthcare to logistics and agriculture, cobots are finding their way into diverse fields.

The rise of cobots is closely tied to advancements in artificial intelligence and machine learning. These technologies have enabled cobots to adapt to changing environments, learn from their tasks, and work in unstructured settings. For example, a cobot in a manufacturing facility can adjust its operations based on the size and shape of the parts it handles, making it a versatile tool for dynamic production lines.

Benefits of Cobots in the Workplace

Cobots are redefining productivity by taking on tasks that are tedious, dangerous, or physically demanding. This allows human workers to shift their focus to areas requiring problem-solving, decision-making, and innovation. For businesses, this translates into a more engaged workforce and improved operational efficiency.

Safety is another critical advantage. Cobots are equipped with sensors that enable them to detect obstacles, including human presence. This reduces the risk of workplace injuries, particularly in hazardous environments. In many cases, cobots can operate alongside humans without the need for additional safety barriers, fostering a more integrated workspace.

From a financial perspective, cobots are cost-effective. Unlike traditional robots, which often require significant upfront investments and specialized infrastructure, cobots are designed to be plug-and-play. Small and medium-sized enterprises (SMEs) can deploy them with minimal disruption, making automation accessible to a wider range of businesses.

Applications of Cobots Across Industries

Cobots are making their mark across various industries, addressing specific needs and challenges in each sector. In manufacturing, cobots assist with assembly, quality control, and inventory management, freeing up workers to focus on more complex tasks. In healthcare, they are used in surgeries, patient monitoring, and laboratory testing, enhancing precision and reducing human error.

In the logistics and transportation sector, cobots streamline operations by automating packaging, sorting, and delivery processes. They are also gaining traction in agriculture, where they handle planting, harvesting, and even monitoring crop health. These versatile robots are proving their worth in retail and e-commerce by optimizing inventory management and improving supply chain efficiency.

Addressing Concerns and Challenges

Despite their many benefits, cobots are not without challenges. One common concern is job displacement. While some fear that cobots might replace human workers, the reality is that they create opportunities by taking on tasks that humans are less suited for. This shift allows workers to transition into roles that require creativity, decision-making, and emotional intelligence — skills that machines cannot replicate.

Another challenge is the cost of implementation. Although cobots are more affordable than traditional robots, the initial investment can still be a barrier for some businesses. To address this, companies can explore leasing options or government incentives designed to support automation adoption.

Training and integration are also critical for the successful implementation of cobots. Businesses must ensure that employees are equipped with the skills needed to work alongside these machines. Upskilling programs and clear communication about the role of cobots can help build trust and acceptance among workers.

Conclusion

The introduction of cobots marks a new chapter in the evolution of the workplace. By combining the strengths of humans and machines, cobots are revolutionizing industries, enhancing productivity, and reshaping the way we work. As businesses prepare to embrace this technology, the potential for growth and innovation is limitless. The future belongs to those who see cobots not as replacements but as partners in progress. Investing in cobots today is an investment in a smarter, safer, and more collaborative workplace tomorrow.